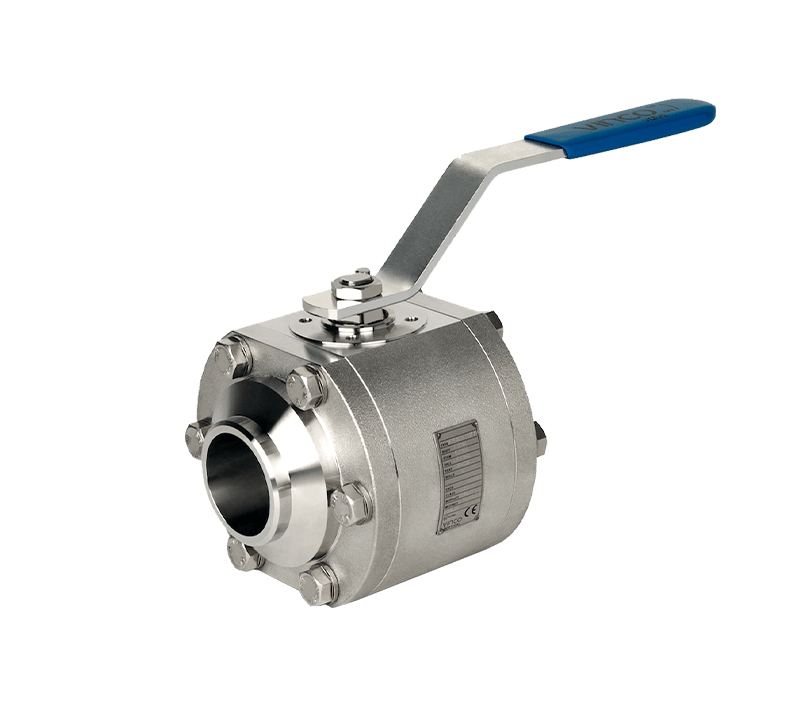

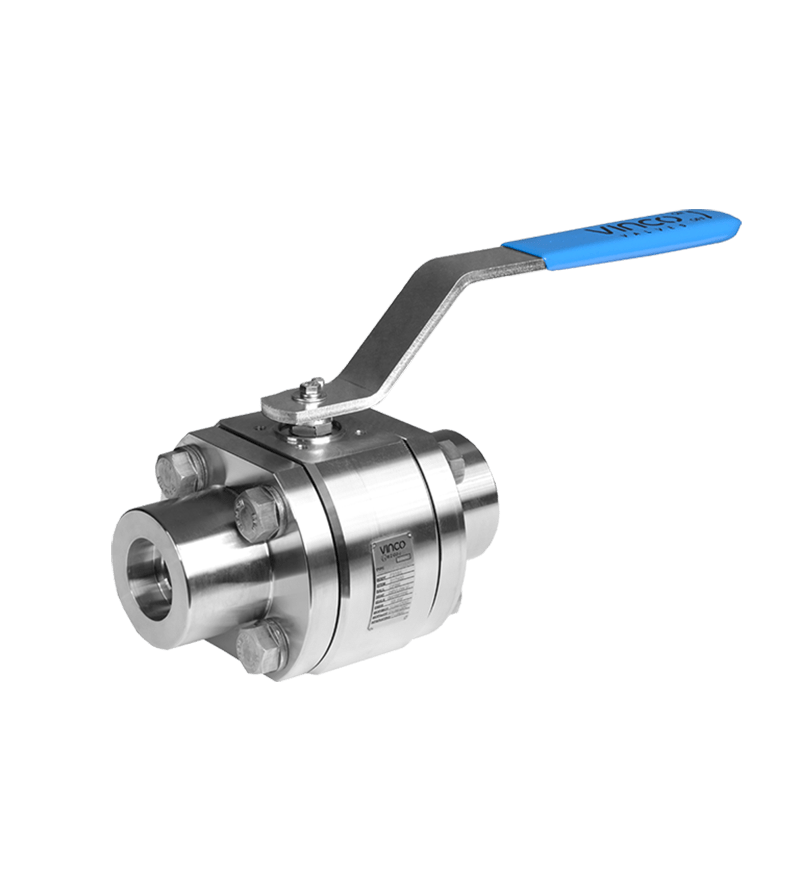

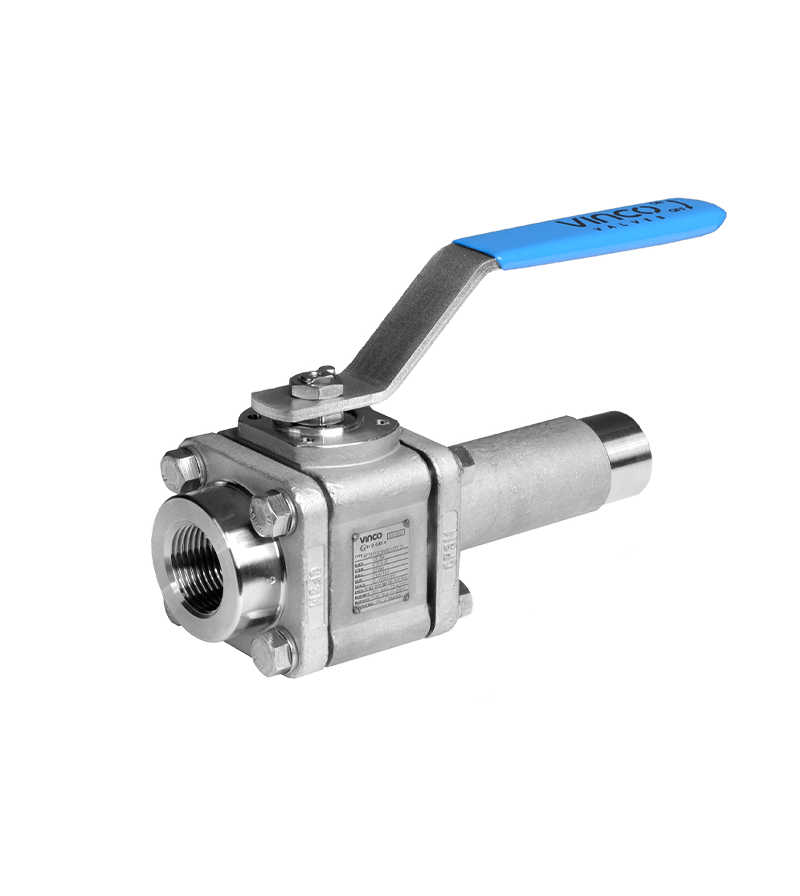

Standard Features:

Floating ball | Soft seated | Full/Reduced bore | Bidirectional

Fire safe design | Antistatic design

Low emission packing | Live loaded stem packing

NACE MR0175 / ISO 15156 compliance

Double encapsulated body sealing

ISO 5211 top works for automation

Anti blowout stem

Self relieving seats | Pressure equalizing hole

Optional Features:

Upstream pressure relief hole

V-Port for flow control applications

Food grade compatible version (CE1935/2004 version)